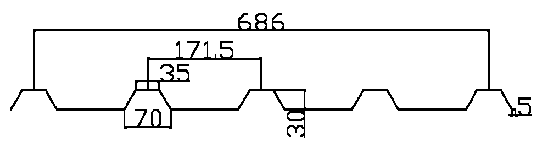

1. Profile |

1.1 Coil material:color Sheet, galvanized sheet 1.2 Coil material thickness:0.25-0.50m 1.3 Feeding coil material wide:914mm |

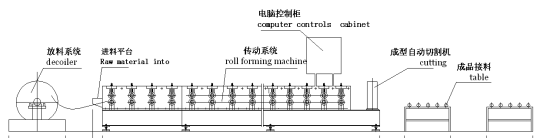

| 2. Process flow | Decoiling--feeding---forming---cutting---production  |

| 3.Electric decoiler | 3.1 Inside diameter coil is 450 - 550mm 3.2 Coil Width is 914 mm 3.3 Coil load 5 ton  |

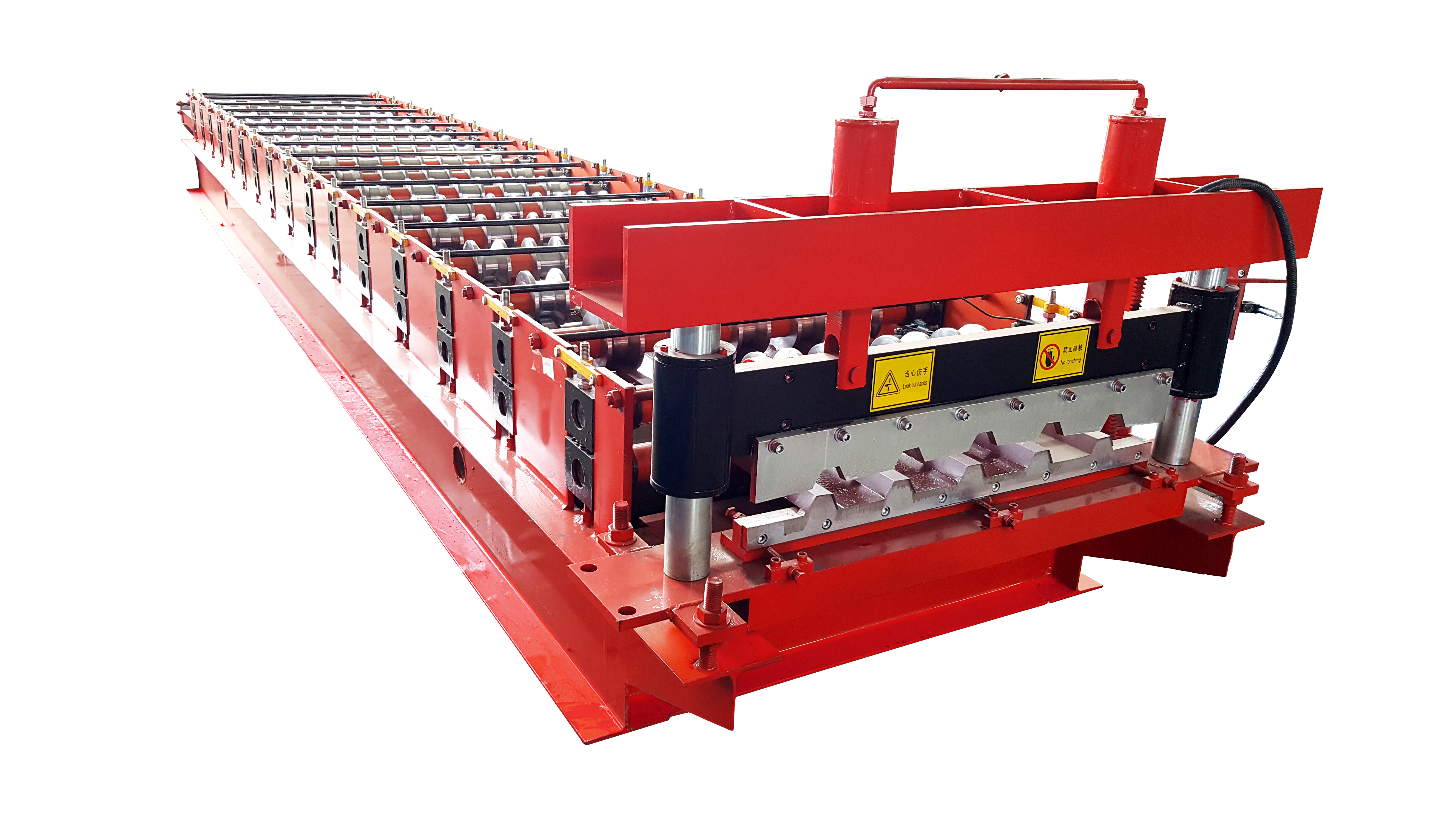

| 4 Forming device | 4.1 Shaft material: 45# steel , outer diameter:70mm 4.2 Roller material: #45 steel with quenching 4.3 Pairs of forming rollers :18 sets 4.4 Chains transport 4.5 Forming speed:10-15 m/min 4.6 Main motor power:4 kw 4.7 Voltage:380v,50Hz,3Phase  |

| 5. Hydraulic Cutting device | 5.1Double Guide Pillar Type Cutting System 5.2Hydraulic Station:1set 5.3 With hydraulic station, motor 4 KW 5.4 Cutting press 20 ton 5.5 Hydraulic cutter 5.6 Blade and mold material: G12 steel with quenched treated 60-62℃ 5.7Cutting system: advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor.  |

| 6.Controlling Device |

6.1 Screen:text screen 6.2 PLC: Delta 6.3 Automatic length measurement 6.4 Automatic quantity measurement 6.5 Computer is used to control length and quantity. Machine will automatically cut to length and stop when required quantity is achieved 6.6 Length inaccuracy can be amended easily  |

| 7. Simple output frame |  1 set 1 set |